PAINTED

Painted glass is tempered glass with glass-ceramic coating, resistant to exposure and belonging to safety glazing group. During tempering the paint is fused into the glass surface to become its inseparable part.

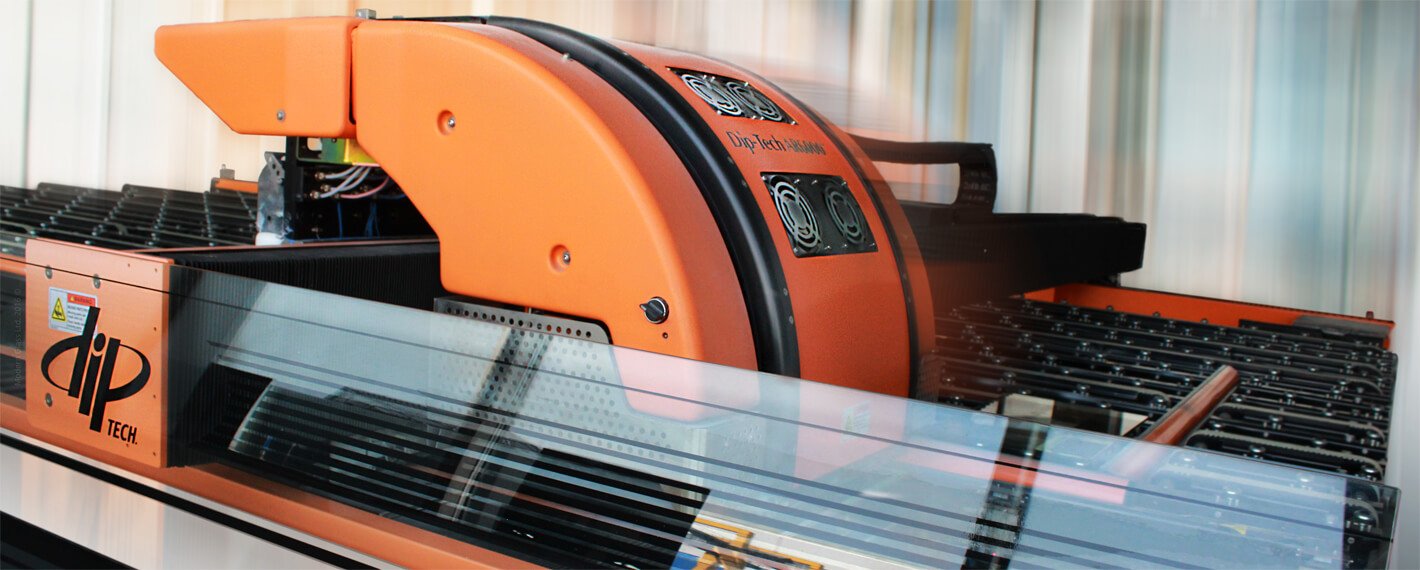

Painting methods: roller, silk-screen, digital. These painting methods are applicable for various types of glass in single products, IGUs and triplexes.

Modern Glass produces painted glass under MG Color (roller and silk-screen printing) and MG MultiColor (digital printing) brands.